MAXIMIZE THE POTENTIAL OF GLASS

BY THIN GLASS OF

"AIMIC SERIES"

For many years, the MICRO TECHNOLOGY Co., has been pursuing glass

materials with strength, hardness and design, and functionality.

I

overcame the image of "hard and heavy", "breaks when force is

applied", and "does not bend".

It is now to realize products

and designs that could not be realized with plastic.

Taking

advantage of the transparency, weather resistance, heat resistance,

wear resistance, etc. of glass, we have developed thin glass "aimic"

with high technology.

We will solve the problems in your

product development and open the door to practical use and

realization.

Products of "aimic"

There are two main products of "aimic",

and there are four

precision processing methods.

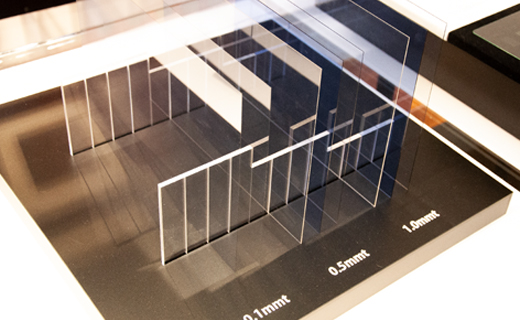

Thin plate glass

It is a simple and plain thin glass product.

We provide the

size as you want with a well-balanced thickness.

Thin precision machined glass

It is a product made by applying ultra-precision

processing

to thin glass.

Precision work

01

strength

Technology for chemical strengthening

-

chemical strengthening processing

Strengthens thin glass.

-

Laminated glass processing

Anti-scattering processing

It is a process to make strong glass with high-precision bonding technology to prevent scattering when broken.

02

Bending

Combination of various processing technologies

-

bendable (bendable) processing

Glass slimming / hybrid processing

Glass that has been thinned to the limit bends like a film.

You can make various shapes such as unique products and 3D products by combining processing technologies such as bonding.

03

Shapes

Shape processing technology

-

Glass cutting technology

NC cutting

Various processing including circular, fan-shaped, drilling, and chamfering.

04

surface treatment

Shape processing technology

-

Glass etching technology

Chemical polishing process

In a large hydrofluoric acid treatment facility, we use glass etching technology to make thin and strong glass. -

High precision printing technology

Decorative printing

High-precision silk printing technology enables high-precision and high-definition colors. It also can decorate curved surfaces. -

Glass surface antireflection technology

AG / AR / AF processing.

AG surface treatment by chemical etching evenly, AR surface treatment with high transmittance and low reflectance, and AF surface treatment with very high antifouling effect are also possible.

Doing these at the same time will result in a higher anti-glare effect. -

Micro wiring processing

It is to form ITO, AI, Mo, Cu, Cr, etc. by vacuum thin film technology.

These are photo fabricated to form a precision wiring pattern.

How "aimic" works

-

01

Increase creativity in product development

-

02

Bring out the

value of product -

03

Expressing

high design -

04

Creating new value

in products

Suggestion of utilization of thin glass ”aimic”

Precision work

-

Automotive

-

Mobile

-

Home

-

Building materials / interior materials

-

Displays

-

Materials for art production

Examples

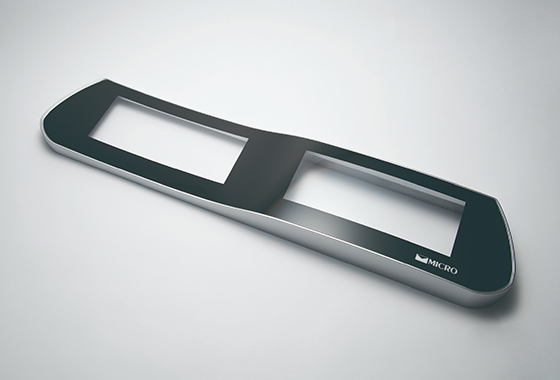

Automotive cover glass

It is a strong glass that meets the demands of curves.

It

can also be fitted to the base stand as an automotive cover

glass.

Unlike plastic, it has a cool image and a

luxurious design. And you can perform decorative printing

processing by AG/AR/AF processing and high precision printing

technology.

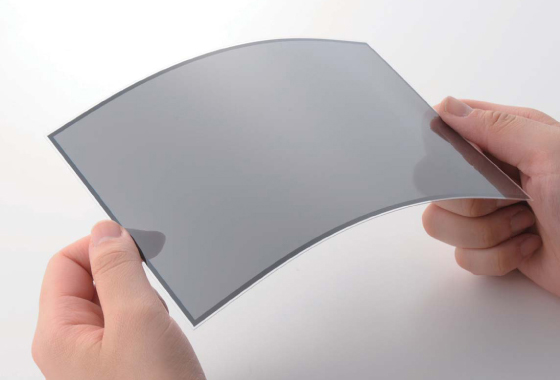

Bending glass

With glass slimming technology, glass that has been thinned to

the limit bends like a film.

Thin film processing

technology can be added to it, and metal wiring processing can

also be performed.

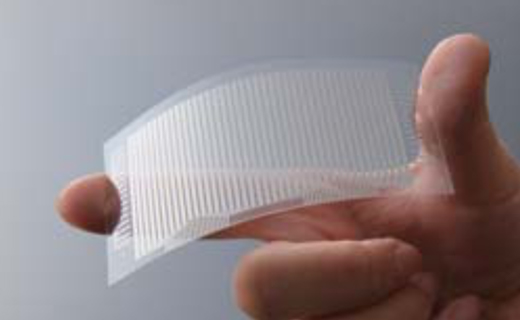

Thin glass sensor

(Bendable capacitive touch panel)

It is a one-sided laminated type capacitive touch panel

developed with the concept of high performance, high

reliability, extremely thin, light, and hard to break even

when bent.

The ultra-thin glass (thickness 0.02mm to

0.05mm) of the sensor part and PET film are bonded together,

and the PET film is film-formed with ITO or the like to block

noise from the LCD panel. Furthermore, by changing the film of

the support, the specifications and applications can be

expanded.

Features of processing technology of

MICRO TECHNOLOGY Co.,

MICRO TECH is good at ultra-precision machining with 50 years of

knowledge, experience, information and technical capabilities.

We

produce unique and original materials as requested.

- 1. We provide everything from processing technology development to Mass Product in at domestic factories.

- 2. We provide high quality, low cost and short delivery time according to customer's specifications.